(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

AKITSU INDUSTRY O-Rings

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 itemsMặt hàng

- Sort By

-

You can add up to 6 items per a category to the compare list.

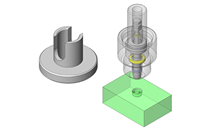

Class 1-A, NBR 70° O-Ring【1-10 Pieces Per Package】

AKITSU INDUSTRY

Class 1-A, NBR 70° O-RingThe O Ring is a commonly employed sealing component found in automation machines across a wide range of industries.[Feature]● Inner Diameter Minimum/ Maximum (mm.) : 2.8 to 149.6● Thickness (mm.) : 1.9, 2.4, 3.5 and 5.7● Applications Environment : Mineral Oil Resistant● Material : Nitrile Rubber (NBR)[Application]O-rings are utilized across multiple industries to prevent the leakage of fluids or gases between two components

Inner Dia. d(Ø) Wire Dia. W(mm) Type Material Environment, Applications 3.8 ~ 149.6 1.9 ~ 5.7 Others Nitrile Rubber Mineral Oil Resistant From: 161,224 VND Days to Ship: Số ngày giao hàng: 4 Day(s) or more  4 Day(s) or more

4 Day(s) or more

| BrandNhãn hiệu |

|---|

| Product SeriesDòng sản phẩm |

| From |

| Days to ShipSố ngày giao hàng |

| Inner Dia. d(Ø) |

| Wire Dia. W(mm) |

| Type |

| Material |

| Environment, Applications |

You can add up to 6 items per a category to the compare list. | |

| BrandNhãn hiệu | AKITSU INDUSTRY |

| Product SeriesDòng sản phẩm | |

| From | 161,224 VND- |

| Days to ShipSố ngày giao hàng | 4 Day(s) or more |

| Inner Dia. d(Ø) | 3.8 ~ 149.6 |

| Wire Dia. W(mm) | 1.9 ~ 5.7 |

| Type | Others |

| Material | Nitrile Rubber |

| Environment, Applications | Mineral Oil Resistant |

Loading...Tải…

ConfigureTạo

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Inner Dia. d(Ø)

- 0.5

- 0.74

- 0.8

- 1

- 1.07

- 1.2

- 1.24

- 1.42

- 1.5

- 1.78

- 1.8

- 2

- 2.06

- 2.2

- 2.24

- 2.4

- 2.5

- 2.57

- 2.8

- 2.84

- 2.9

- 3

- 3.15

- 3.2

- 3.5

- 3.55

- 3.63

- 3.68

- 3.75

- 3.8

- 4

- 4.2

- 4.34

- 4.42

- 4.47

- 4.5

- 4.7

- 4.75

- 4.8

- 4.84

- 4.87

- 5

- 5.15

- 5.23

- 5.28

- 5.3

- 5.4

- 5.5

- 5.6

- 5.75

- 5.8

- 5.94

- 6

- 6.02

- 6.07

- 6.3

- 6.4

- 6.5

- 6.7

- 6.75

- 6.8

- 6.9

- 7

- 7.1

- 7.4

- 7.5

- 7.52

- 7.59

- 7.64

- 7.65

- 7.8

- 8

- 8.4

- 8.5

- 8.75

- 8.8

- 8.92

- 9

- 9.12

- 9.19

- 9.25

- 9.4

- 9.5

- 9.7

- 9.8

- 10

- 10.4

- 10.46

- 10.5

- 10.52

- 10.6

- 10.69

- 10.7

- 10.77

- 10.8

- 10.82

- 11

- 11.2

- 11.5

- 11.7

- 11.8

- 11.89

- 12

- 12.06

- 12.29

- 12.3

- 12.37

- 12.4

- 12.42

- 12.5

- 13

- 13.2

- 13.46

- 13.5

- 13.64

- 13.7

- 13.8

- 13.87

- 13.94

- 14

- 14.4

- 14.5

- 14.8

- 15

- 15.24

- 15.4

- 15.47

- 15.5

- 15.54

- 15.6

- 15.8

- 16

- 16.36

- 16.4

- 16.5

- 16.8

- 16.81

- 17

- 17.04

- 17.12

- 17.17

- 17.4

- 17.5

- 17.7

- 17.8

- 17.93

- 18

- 18.42

- 18.5

- 18.64

- 18.72

- 18.77

- 18.8

- 19

- 19.18

- 19.4

- 19.5

- 19.7

- 19.8

- 19.99

- 20

- 20.22

- 20.29

- 20.35

- 20.5

- 20.8

- 21

- 21.2

- 21.4

- 21.5

- 21.59

- 21.7

- 21.8

- 21.82

- 21.89

- 21.9

- 21.92

- 21.95

- 22

- 22.1

- 22.4

- 23.16

- 23.3

- 23.39

- 23.4

- 23.46

- 23.47

- 23.5

- 23.52

- 23.6

- 23.7

- 24

- 24.4

- 24.5

- 24.7

- 24.76

- 24.99

- 25

- 25.04

- 25.07

- 25.12

- 25.2

- 25.5

- 25.7

- 25.8

- 26

- 26.2

- 26.34

- 26.5

- 26.57

- 26.59

- 26.64

- 26.7

- 27.5

- 27.7

- 27.94

- 28

- 28.17

- 28.24

- 28.3

- 28.5

- 28.7

- 29

- 29.2

- 29.4

- 29.5

- 29.51

- 29.7

- 29.74

- 29.82

- 29.87

- 30

- 30.7

- 31

- 31.12

- 31.2

- 31.34

- 31.42

- 31.47

- 31.5

- 31.7

- 32

- 32.5

- 32.69

- 32.92

- 32.99

- 33

- 33.05

- 33.2

- 33.5

- 33.7

- 34

- 34.29

- 34.4

- 34.42

- 34.5

- 34.52

- 34.59

- 34.65

- 34.7

- 35

- 35.2

- 35.5

- 35.7

- 36

- 36.09

- 36.17

- 36.5

- 37.2

- 37.46

- 37.5

- 37.6

- 37.69

- 37.7

- 37.77

- 37.82

- 38

- 38.5

- 38.7

- 39

- 39.34

- 39.4

- 39.5

- 39.7

- 40

- 40.64

- 40.7

- 40.87

- 40.94

- 41

- 41.2

- 41.5

- 41.7

- 42

- 42.2

- 42.5

- 42.52

- 43

- 43.5

- 43.69

- 43.7

- 43.82

- 44

- 44.04

- 44.12

- 44.17

- 44.4

- 44.5

- 44.7

- 45

- 45.5

- 45.69

- 45.7

- 46

- 46.2

- 46.99

- 47.22

- 47.29

- 47.35

- 47.5

- 47.6

- 47.7

- 48

- 48.7

- 48.89

- 48.9

- 49

- 49.4

- 49.5

- 49.6

- 49.7

- 50

- 50.16

- 50.39

- 50.47

- 50.52

- 51.4

- 51.5

- 51.6

- 52

- 52.07

- 52.5

- 52.6

- 53

- 53.09

- 53.34

- 53.57

- 53.64

- 53.7

- 54.4

- 54.5

- 54.6

- 55

- 55.24

- 55.5

- 55.6

- 56

- 56.52

- 56.74

- 56.82

- 56.87

- 57.4

- 57.5

- 57.6

- 58

- 58.42

- 59

- 59.36

- 59.4

- 59.5

- 59.6

- 59.69

- 59.92

- 59.99

- 60

- 60.05

- 61.4

- 61.5

- 61.59

- 61.6

- 62

- 62.4

- 62.5

- 62.6

- 62.86

- 63

- 63.09

- 63.17

- 63.22

- 63.4

- 64.4

- 64.5

- 64.6

- 64.77

- 65

- 66.04

- 66.27

- 66.34

- 66.4

- 66.5

- 66.6

- 67

- 67.94

- 69

- 69.22

- 69.4

- 69.44

- 69.5

- 69.52

- 69.57

- 69.6

- 70

- 70.5

- 70.6

- 71

- 71.12

- 71.4

- 72

- 72.39

- 72.62

- 72.69

- 72.75

- 73

- 74

- 74.4

- 74.5

- 74.6

- 75

- 75.56

- 75.79

- 75.87

- 75.92

- 77.5

- 78.74

- 78.97

- 79

- 79.4

- 79.5

- 79.6

- 80

- 81.92

- 82.14

- 82.22

- 82.27

- 82.5

- 84

- 84.4

- 84.5

- 84.6

- 85

- 85.09

- 85.32

- 87.5

- 88.26

- 88.49

- 88.57

- 88.62

- 89

- 89.4

- 89.5

- 89.6

- 90

- 91.44

- 91.67

- 92.5

- 94

- 94.4

- 94.5

- 94.6

- 94.62

- 94.67

- 94.84

- 94.92

- 94.97

- 95

- 97.5

- 97.79

- 98.02

- 99

- 99.4

- 99.5

- 99.6

- 100

- 100.96

- 101.19

- 101.27

- 101.32

- 101.6

- 102

- 103

- 104

- 104.14

- 104.37

- 104.4

- 104.5

- 104.6

- 105

- 105.6

- 106

- 107.32

- 107.54

- 107.62

- 107.67

- 109

- 109.4

- 109.5

- 109.6

- 110

- 110.49

- 110.72

- 111.5

- 111.6

- 112

- 113.66

- 113.89

- 113.97

- 114

- 114.02

- 114.4

- 114.5

- 114.6

- 115

- 116.84

- 117.07

- 117.6

- 118

- 119

- 119.4

- 119.5

- 119.6

- 120

- 120.02

- 120.24

- 120.32

- 120.37

- 122

- 123.19

- 123.42

- 124

- 124.4

- 124.5

- 124.6

- 125

- 126.36

- 126.59

- 126.67

- 126.72

- 128

- 129

- 129.4

- 129.5

- 129.54

- 129.6

- 129.77

- 130

- 131.5

- 131.6

- 132

- 132.72

- 132.94

- 133.02

- 133.07

- 134

- 134.4

- 134.5

- 134.6

- 135

- 135.89

- 136

- 136.12

- 138

- 139.06

- 139.07

- 139.29

- 139.37

- 139.4

- 139.5

- 139.6

- 140

- 142.24

- 142.47

- 143.5

- 144.4

- 144.5

- 144.6

- 145

- 145.42

- 145.64

- 145.72

- 148.5

- 148.59

- 148.82

- 149.3

- 149.5

- 149.6

- 150

- 151.76

- 151.77

- 151.99

- 152.07

- 153

- 154.3

- 154.5

- 155

- 158

- 158.12

- 158.34

- 158.42

- 159.3

- 159.5

- 160

- 163

- 164.3

- 164.46

- 164.47

- 164.5

- 164.69

- 164.77

- 165

- 168

- 169.3

- 169.5

- 170

- 170.82

- 171.04

- 171.12

- 173

- 174.3

- 174.5

- 175

- 177.16

- 177.17

- 177.39

- 177.47

- 178

- 179.3

- 179.5

- 180

- 183.52

- 183.74

- 183.82

- 184.3

- 184.5

- 185

- 189.3

- 189.5

- 189.86

- 189.87

- 190

- 190.09

- 190.17

- 193

- 194.3

- 194.5

- 195

- 196.22

- 196.44

- 196.52

- 198

- 199.3

- 199.5

- 200

- 202.56

- 202.57

- 202.79

- 202.87

- 203

- 204.3

- 204.5

- 205

- 206

- 208

- 208.5

- 208.92

- 209

- 209.14

- 209.22

- 209.3

- 209.5

- 210

- 212

- 213

- 214.3

- 214.5

- 215

- 215.26

- 215.27

- 215.49

- 215.57

- 218

- 219.3

- 219.5

- 220

- 221.62

- 221.84

- 221.92

- 222.5

- 224

- 224.3

- 224.5

- 225

- 227.5

- 227.96

- 227.97

- 228.19

- 228.27

- 229.3

- 229.5

- 230

- 232.5

- 234.3

- 234.32

- 234.5

- 234.54

- 234.62

- 235

- 236

- 237.5

- 239.3

- 239.5

- 240

- 240.66

- 240.67

- 240.89

- 240.97

- 242.5

- 243

- 244.3

- 244.5

- 245

- 247.02

- 247.24

- 247.32

- 247.5

- 247.67

- 249.3

- 249.5

- 250

- 253.36

- 253.37

- 253.59

- 254.3

- 254.5

- 255

- 257.5

- 258

- 259.3

- 259.5

- 260

- 262.5

- 264.3

- 264.5

- 265

- 266.06

- 266.07

- 266.29

- 269.3

- 269.5

- 270

- 272

- 274.3

- 274.5

- 275

- 277

- 278.76

- 278.77

- 278.99

- 279.3

- 279.5

- 280

- 284.3

- 284.5

- 285

- 289.3

- 289.5

- 290

- 291.46

- 291.47

- 291.69

- 292

- 294.3

- 294.5

- 295

- 299.3

- 299.5

- 300

- 304.15

- 304.16

- 304.17

- 304.39

- 304.5

- 305

- 307

- 309.3

- 309.5

- 310

- 314.3

- 314.5

- 315

- 316.86

- 316.87

- 317

- 319.3

- 319.5

- 320

- 321.5

- 324.3

- 324.5

- 325

- 329.3

- 329.5

- 329.56

- 329.57

- 329.79

- 330

- 334.3

- 334.5

- 335

- 339.3

- 339.5

- 340

- 342.26

- 342.27

- 344.3

- 344.4

- 344.5

- 345

- 349.3

- 349.5

- 350

- 354.3

- 354.5

- 354.96

- 354.97

- 355

- 355.19

- 359.3

- 359.5

- 360

- 364.3

- 364.5

- 365

- 367.66

- 367.67

- 369.3

- 369.5

- 370

- 371.5

- 374.3

- 374.5

- 375

- 376

- 379.3

- 379.5

- 380

- 380.36

- 380.37

- 380.59

- 381

- 384.3

- 384.5

- 385

- 386

- 387

- 389.3

- 390

- 393.06

- 393.07

- 394.3

- 395

- 396

- 399.3

- 399.5

- 400

- 404.3

- 405

- 405.26

- 406

- 409.3

- 410

- 411

- 412

- 414.3

- 415

- 416

- 417.96

- 419.3

- 420

- 424.3

- 425

- 425.5

- 430

- 430.5

- 430.66

- 434.3

- 434.5

- 435

- 437

- 439.5

- 440

- 443.36

- 444.3

- 445

- 450

- 454.5

- 455

- 456.06

- 456.07

- 459.3

- 460

- 460.5

- 462

- 464.5

- 465

- 468.76

- 470

- 470.5

- 474.3

- 475

- 479.3

- 480

- 481.46

- 484.3

- 485

- 487

- 489.3

- 490

- 494.16

- 494.3

- 494.5

- 495

- 499.3

- 499.5

- 500

- 504.5

- 506.86

- 515

- 519.3

- 519.5

- 524.3

- 524.5

- 529.5

- 530

- 532.26

- 544

- 545

- 549.3

- 549.5

- 554.5

- 557.66

- 560

- 569.3

- 579

- 580

- 582.68

- 589.3

- 599.3

- 600

- 603.5

- 608.08

- 615

- 630

- 633.48

- 633.5

- 643

- 650

- 658.88

- 670

- 683

- 732.5

- 759.3

- 762

- 782

- 791.5

- 811.5

- 821.5

- 836.5

- 839.5

- 841.5

- 899.3

- 911

- 939.5

- 940.5

- 960.5

- 1044

-

Wire Dia. W(mm)

-

Type

- P (For Mounting, Dynamic)

- G (For Mounting)

- V (For Vacuum Flanges)

- S (for Low Voltage Mounting)

- SS (for Low Voltage Mounting)

- AS (For Mounting)

- JASO (For Mounting, Dynamic)

- ISO (for general industrial applications)

- Configurable

- Back-Up Ring

- Others

-

Material

- Nitrile Rubber

- Ethylene Propylene Rubber

- Silicon Rubber

- Fluoro Rubber

- Urethane Rubber

- Fluororesin

-

Environment, Applications

- Mineral Oil Resistant

- Gasoline Resistant

- Animal and Vegetable Oil Resistant

- Heat Resistant

- Coolant Resistant

- Abrasion Resistant

- Pressure Resistant

- Chemical Resistant

- Weather Resistant

- Cold Resistant

- Water Resistant

- Hot Water-resistant

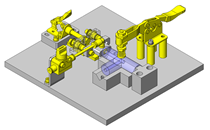

Application example related to this categoryVí dụ ứng dụng liên quan đến danh mục này

Related Categories to O-RingsDanh mục liên quan đến O-Rings

FAQ O-Ring

- Question: What are the main applications of O-rings?

- Answer: O-rings have several key applications across various industries. Here are their main uses:

1. Hydraulics and Pneumatics: O-rings find extensive use in hydraulic and pneumatic systems. They seal fittings, connectors, and control valves, maintaining pressure integrity and preventing leaks in these systems.

2. Automotive Industry: O-rings play a crucial role in automotive applications, including engines, fuel systems, brake systems, and air conditioning systems. They provide effective sealing to prevent fluid leaks,

leaks.

3. Industrial Machinery: O-rings are widely utilized in manufacturing and machinery, such as pumps, compressors, valves, and cylinders. They seal these components, preventing leakage and ensuring efficient operation.

4. Medical Equipment: O-rings are utilized in medical devices like syringes, catheters, and pumps.

5. Plumbing and Water Systems: O-rings are commonly found in plumbing fittings, faucets, and valves. - Question: How do I select the right O-ring size for my application?

- Answer: To select the right O-ring size for your application, you need to consider the following factors:

1. Inner Diameter (ID) and Outer Diameter (OD): The ID of the O-ring should match the groove diameter, and the OD should be slightly larger to ensure proper sealing.

2. Cross-Sectional Diameter or thickness of O-ring : It should be compatible with the groove's width or depth to provide an adequate seal.

3. Material : Consider the material of the O-ring to ensure compatibility with the fluid or gas in your application. Different materials have varying chemical resistance, temperature tolerance, and physical properties.

4. Compression and Stretch: Determine the compression and stretch limits of the O-ring material to ensure it can adequately seal the mating surfaces without being overcompressed or overstretched.

5. Standards and Guidelines: Consult industry standards, such as AS568 (for inch sizes) or ISO 3601 (for metric sizes), to understand the standard sizes available and their corresponding tolerances.

6. Consider O-ring Sizing Guides: O-ring manufacturers often provide sizing guides or calculators that help select the appropriate O-ring size based on application parameters. - Question: Is an O-ring a gasket? Can I replace O-ring with gasket?

- Answer: Yes, an O-ring is a type of gasket.

Yes with condition, an O-ring can be considered a type of gasket. Both O-rings and gaskets are used for sealing applications to prevent fluid or gas leakage. However, O-rings have a specific circular shape look like a doughnut while gaskets come in various shapes and designs.

In some cases, an O-ring can be replaced with a gasket depending on the application. However, it is essential to consider factors such as size, shape, material compatibility, and the specific sealing requirements of the application. Consulting with the equipment manufacturer or a sealing specialist can help determine the most suitable replacement option. - Question: How often should O-rings be replaced?

- Answer: The frequency of O-ring replacement varies based on factors like application, operating conditions, and material type. Here are some general guidelines:

1. Visual Inspection: Regularly inspect O-rings for wear, damage, or deformation. Replace if tears or flattening are observed.

2. Leakage: If there is noticeable fluid or gas leakage, consider replacing the O-ring.

3. Age and Service Life: Follow manufacturer's recommendations or industry standards for the expected service life of the O-ring material.

4. Maintenance Schedule: Adhere to the equipment manufacturer's maintenance plan, which may include periodic O-ring replacement as preventive maintenance.

5. Environmental Factors: Consider temperature extremes, chemical exposure, and high-pressure environments, which can accelerate O-ring deterioration and require more frequent replacement. - Question: Do O-rings need to be lubricated?

- Answer: Yes, O-rings typically require lubrication for optimal performance. Lubrication helps reduce friction between the O-ring and the surfaces it contacts, extending its lifespan and improving sealing efficiency. The lubricant acts as a barrier, preventing excessive wear and ensuring smooth movement. It is important to select a compatible lubricant that suits the application's temperature range and the O-ring material. While some O-ring materials are self-lubricating, lubrication is generally recommended unless specific circumstances dictate otherwise. Consulting manufacturer guidelines and considering the specific application requirements are essential for determining the need for lubrication.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy