(!) Since support from Microsoft will end on January 14th, 2020, Windows 7 will be excluded from the recommended environment from December 15th, 2019 on this site. Vì lý do Microsoft kết thúc hỗ trợ cho Windows 7 vào ngày 14/01/2020, Windows 7 sẽ là hệ điều hành không được khuyến khích sử dụng với trang web này từ ngày 15/12/2019.

Search by Category / Brand Tìm theo danh mục, nhãn hiệu

Search by Category Tìm theo danh mục

- [Thông báo] Cập nhật địa chỉ kho tập kết hàng hóa tại khu vực miền Nam của MISUMI Việt Nam. Xem chi tiết.

[Announcement] Update on warehouse address in the Southern region of MISUIMI Vietnam. See more. - [Cảnh Báo] Thủ Đoạn Lừa Đảo Từ Nhân Viên Giao Hàng – Yêu Cầu Trả Phí Ship. Xem chi tiết.

[Warning] Fraud Calling from Shipper - Asking to Pay Shipping Fee. See more.

Specification/DimensionsĐặc điểm kỹ thuật / Kích thướcĐặc điểm kỹ thuật / Kích thước

-

Ball Screw Dia.(φ)

- 15

- 20

-

Ball Screw Lead(mm)

- 10

- 20

-

Overall Base Length [L](mm)

-

type

- E-KUAC

-

CADCAD

- 2D

- 3D

Days to ShipSố ngày giao hàng

-

- Alltất cả các

- 40 Day(s) or Less

Specify AlterationsChỉ định thay đổi

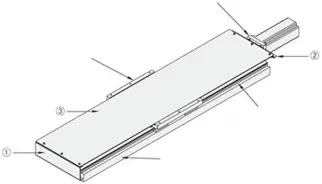

Single Axis Units Rolled Ball Screw With Cover

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Overview of Belt Actuators/Drives and Accessories

Belt Actuators/Drives and Accessories E-KUA/E-KUAC single axis unit, which has standardized

the mechanism self-made by the customer with high usage frequency, is driven by rolled/precision ball screw to achieve high precision positioning. High-load transfer is also made possible by using a linear guide for medium and heavy load.

Belt Actuators/Drives and Accessories, A single axis unit with cover can prevent damage to the single axis unit caused by dropping small parts, etc., and prevent liquids

such as adhesive or grease from dripping inside the single axis unit. Safe use is ensured, significantly reducing magement costs.

the mechanism self-made by the customer with high usage frequency, is driven by rolled/precision ball screw to achieve high precision positioning. High-load transfer is also made possible by using a linear guide for medium and heavy load.

Belt Actuators/Drives and Accessories, A single axis unit with cover can prevent damage to the single axis unit caused by dropping small parts, etc., and prevent liquids

such as adhesive or grease from dripping inside the single axis unit. Safe use is ensured, significantly reducing magement costs.

Product Features of Belt Actuators/Drives and Accessories

Feature 1 : Belt Actuators/Drives and Accessories high precision. Achieves high precision positioning through the combination of linear guide and ball screw.

Feature 2 : Belt Actuators/Drives and Accessories low cost. Saves time in design, procurement and assembly. Significantly reduces labor costs for customers.

Feature 3 : Belt Actuators/Drives and Accessories heavy load resistance. Suitable for high and heavy load transfer thanks to the use of a linear guide for medium and heavy load.

Feature 2 : Belt Actuators/Drives and Accessories low cost. Saves time in design, procurement and assembly. Significantly reduces labor costs for customers.

Feature 3 : Belt Actuators/Drives and Accessories heavy load resistance. Suitable for high and heavy load transfer thanks to the use of a linear guide for medium and heavy load.

Structure Features of Belt Actuators/Drives and Accessories

Belt Actuators/Drives and Accessories, Adopts a lightweight aluminum base with high rigidity, featuring a ball linear guide.

Driven by rolled screw, two products (without cover type and with cover type) are added to the lineup.

Driven by rolled screw, two products (without cover type and with cover type) are added to the lineup.

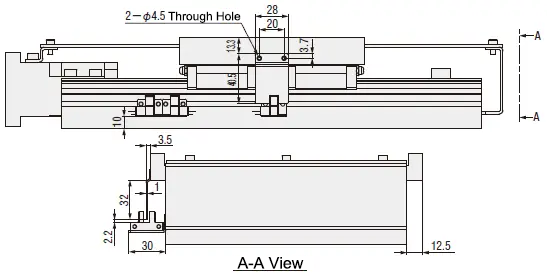

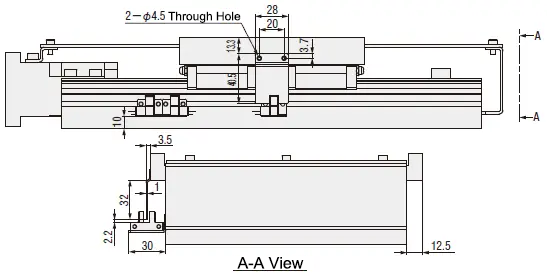

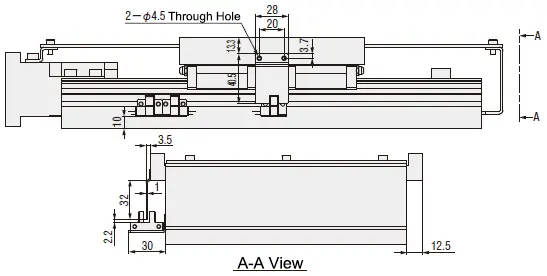

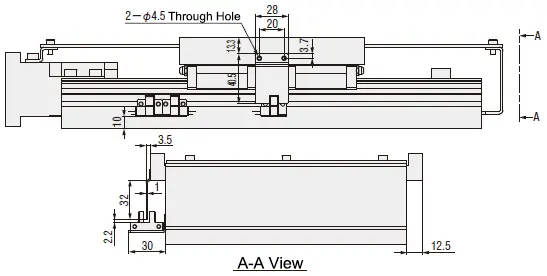

Dimensional Drawing of Belt Actuators/Drives and Accessories

Accessories Accessories |  Material Material |  Surface Treatment Surface Treatment | Quantity | Note |

| Hexagon socket head bolt M5×10 | Iron | Trivalent Chromate Treatment (Black) | 4 | For fixing bracket |

| Part | Base | Table | Motor Bracket | Nut Bracket | Fixed Side Screw Support Unit | Support Side Bearing Housing | Stopper |

Material Material | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Iron | Aluminum Alloy | Resin |

Surface Treatment Surface Treatment | Black Anodized | Black Anodized | Black Anodized | Black Anodized | Ferroferric Oxide Protective Film | Black Anodized | - |

Specification Table of Belt Actuators/Drives and Accessories

| Part Number | Selection | Rolled Ball Screw | W Workbench Width | H Total Height | H1 Guide Height | H2 Axis Height | Table | |||||||

Type Type |  No. No. |  L LBase Length |  L1 L1Table Length | Diameter | Lead | W | t2 | M1 | P1 | P2 | ||||

| E-KUAC | 1510L 1520L | 340 | 150 | 15 | 10 20 | 220 | 74 | 28 | 32 | 220 | 22 | M5 | 120 | 195 |

| 400 | ||||||||||||||

| 460 | ||||||||||||||

| 520 | ||||||||||||||

| 580 | ||||||||||||||

| 2010L 2020L | 20 | 89 | 39 | 40 | ||||||||||

| 640 | ||||||||||||||

| 700 | ||||||||||||||

| 78 | 28 | 34 | ||||||||||||

| 760 | ||||||||||||||

| 820 | ||||||||||||||

| Part Number | Base | Base Mounting Hole | Motor Mounting Related Dimensions | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Type | No. | W1 | H4 | t1 | h1 | P3 | h | Q | S | P.C.D | D | D1 | H3 | N | N1 | N2 | N3 | d | M2 | R | ||||||||||||||||||||||||||||||||||||||||

| E-KUAC | 1510L 1520L | 208 | 49 | 12 | 20 | 120 | 11.5 |

|

| 70 | 50 | 45 | 62 | 45 | 5 | 40 | 15 | 10 | M5 | 10 | ||||||||||||||||||||||||||||||||||||||||

| 2010L | 61 | 29 | 70 | 57.5 | 39.5 | 20 | 12 | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2020L | 55 | 20 | 64 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

*L=340 is suitable for 1510L only, and L=400 is suitable for 1510L and 2010L only.

■ Applicable Servo Motor Table

■ Precision·Allowable Static Load

■ Applicable Servo Motor Table

| Manufacturers | Part Number | Output Power (W) | Square Flange |

| Yaskawa Electric | SGM7J-02 | 200 | □60 |

| SGM7J-04 | 400 | ||

| Mitsubishi Electric | HG-MR23 | 200 | |

| HG-KR23 | 200 | ||

| HF-MP23 | 200 | ||

| HF-KP23 | 200 | ||

| HG-MR43 | 400 | ||

| HG-KR43 | 400 | ||

| HF-MP43 | 400 | ||

| HF-KP43 | 400 |

■ Precision·Allowable Static Load

| Part Number | *Positioning Repeatability (mm) | Allowable Static Load (kg) | *Parallelism (mm) | ||||||||||||||||||||||

| Type | No. | Horizontal | Vertical | ||||||||||||||||||||||

| Rolled Ball Screw E-KUAC | 1510L | ±0.05 | 2897 | 153 |

| ||||||||||||||||||||

| 1520L | |||||||||||||||||||||||||

| 2010L | 4345 | 169 | |||||||||||||||||||||||

| 2020L | |||||||||||||||||||||||||

■ Ball Screw Coupling Side Shaft End Alterations

| Alterations | Code | Spec. | |||||||

| Machining fixed side shaft end keyways | KC | Adds keyways. KC= 1mm increments Ordering Code KC10 |

| ||||||

| |||||||||

| Machining fixed side shaft end keyways | KLC | The machining position of keyways can be specified. K, S= 1mm increments Ordering Code KLC-K5-S2 |

| ||||||

| |||||||||

| Machining fixed side shaft end plane | SC | Adds planes. SC= 1mm increments Ordering Code SC7 |

| ||||||

| |||||||||

| Machining a plane at fixed side shaft end (2 places) | SWC | Adds planes at 2 places (90° position). SWC= 1mm increments Ordering Code SWC7 |

| ||||||

| |||||||||

■ Single Axis Actuators Cover Specification Optical Sensor

■ Cover Specification Optical Sensor Dimensions Table

| Applicable Part Number | Code |

| E-KUAC 1510L/1520L | CW1 CW2 CW3 |

| E-KUAC 2010L/2020L |

Example Use of Belt Actuators/Drives and Accessories

(1) Deburring Equipment Unit

Model : E-KUAC1505-340-150

Description : Movement of deburring brush. Especially suitable for working conditions with variable lifting speed and durability requirements.

Application : A sufficiently rigid device is required to prevent vibration.

Model : E-KUAC1505-340-150

Description : Movement of deburring brush. Especially suitable for working conditions with variable lifting speed and durability requirements.

Application : A sufficiently rigid device is required to prevent vibration.

(2) Movable Grinding Head Unit

Model : E-KUHC2010L-400-200

Description : Movement and positioning for bending and grinding equipment of crankshafts.

Application : The part of the device that deviates from the base plate.

Model : E-KUHC2010L-400-200

Description : Movement and positioning for bending and grinding equipment of crankshafts.

Application : The part of the device that deviates from the base plate.

(3) Welding Head Unit

Model: E-KUAC2010L-580-200

Description: Movement and positioning of the sliding part during equidistant welding operations of section steel spot welding machines.

Application: A sufficiently rigid device is required to prevent clamping.

Model: E-KUAC2010L-580-200

Description: Movement and positioning of the sliding part during equidistant welding operations of section steel spot welding machines.

Application: A sufficiently rigid device is required to prevent clamping.

Application Industries of Belt Actuators/Drives and Accessories

Usage Method of Belt Actuators/Drives and Accessories

■ Mounting Method of Belt Actuators/Drives and Accessories

Mount by positioning on the side of the base.

To ensure the precision of the single axis unit, fix it to an iron plate with flatness of ±0.02mm or less and

To ensure the precision of the single axis unit, fix it to an iron plate with flatness of ±0.02mm or less and

thickness of 20mm or more through the mounting holes of the base, otherwise the base will be deformed and jamming will occur.

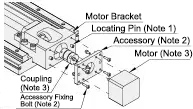

(1) Accessory Installation Diagram of Belt Actuators/Drives and Accessories

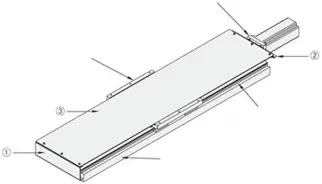

(2) Cover Installation Procedure of Belt Actuators/Drives and Accessories

Step 1 : Fix the KU□C body on the device or workbench used by the customer.

Step 2 : Install the attached brackets ①② onto the body.

Step 3 : Fix the attached cover ③ onto the attached brackets ①② already installed in Step 2.

■ Belt Actuators/Drives and Accessories Maintenance Method

(1) Grease Replenishment Method

After applying grease directly to the ball screw, slide the workbench over the full stroke to achieve overall uniform application.

Insert the grease gun into the nozzle on the linear guide and inject grease.

After injection, move the table over the full stroke several times to achieve overall uniform application.

Grease: Showa Shell Albania Grease S2.

Grease: Showa Shell Albania Grease S2.

(2) Frequency of Grease Replenishment

Replenish grease every 6 months (or when the travel distance reaches 1000KM).

The replenishment interval varies with operating conditions and operating environment. Please make appropriate judgments.

The replenishment interval varies with operating conditions and operating environment. Please make appropriate judgments.

Mount by positioning on the side of the base.

To ensure the precision of the single axis unit, fix it to an iron plate with flatness of ±0.02mm or less and

To ensure the precision of the single axis unit, fix it to an iron plate with flatness of ±0.02mm or less andthickness of 20mm or more through the mounting holes of the base, otherwise the base will be deformed and jamming will occur.

(1) Accessory Installation Diagram of Belt Actuators/Drives and Accessories

Note 1. Dowel pin is pressed into the motor bracket.

Note 2. Accessory and 4 M3x10 fixing bolts are included.

Note 3. Motor and coupling are not included.

Note 2. Accessory and 4 M3x10 fixing bolts are included.

Note 3. Motor and coupling are not included.

(2) Cover Installation Procedure of Belt Actuators/Drives and Accessories

Step 1 : Fix the KU□C body on the device or workbench used by the customer.

Step 2 : Install the attached brackets ①② onto the body.

Step 3 : Fix the attached cover ③ onto the attached brackets ①② already installed in Step 2.

■ Belt Actuators/Drives and Accessories Maintenance Method

(1) Grease Replenishment Method

After applying grease directly to the ball screw, slide the workbench over the full stroke to achieve overall uniform application.

Insert the grease gun into the nozzle on the linear guide and inject grease.

After injection, move the table over the full stroke several times to achieve overall uniform application.

Grease: Showa Shell Albania Grease S2.

Grease: Showa Shell Albania Grease S2.(2) Frequency of Grease Replenishment

Replenish grease every 6 months (or when the travel distance reaches 1000KM).

The replenishment interval varies with operating conditions and operating environment. Please make appropriate judgments.

The replenishment interval varies with operating conditions and operating environment. Please make appropriate judgments.Precautions of Belt Actuators/Drives and Accessories

■ Belt Actuators/Drives and Accessories Arrival and Usage :

(1) The sensor unit, cover and the single axis unit are shipped in the same package. The customer installs by himself.

(2) Due to the large number of fine parts, please check the supplied parts immediately after unpacking.

(3) Turn on the power and use the product after ensuring safety in the surroundings, thus avoiding equipment damage or personal injury accidents.

■ Operating Environment of Belt Actuators/Drives and Accessories

Use at an ambient temperature of 50°C or less. Recommended operating temperature: 0 to 50℃ (without freezing or condensation).

■ Avoid using the Belt Actuators/Drives and Accessories single axis unit in the following environments

(1) The sensor unit, cover and the single axis unit are shipped in the same package. The customer installs by himself.

(2) Due to the large number of fine parts, please check the supplied parts immediately after unpacking.

(3) Turn on the power and use the product after ensuring safety in the surroundings, thus avoiding equipment damage or personal injury accidents.

■ Operating Environment of Belt Actuators/Drives and Accessories

Use at an ambient temperature of 50°C or less. Recommended operating temperature: 0 to 50℃ (without freezing or condensation).

■ Avoid using the Belt Actuators/Drives and Accessories single axis unit in the following environments

(1) Dusty environment (especially metal powder)

(2) Environment with splashing water and oil

(3) Near fire sources

(4) Environment with excessive organic solutions and salt

(5) Environment with direct sunlight and heat radiation

(6) Environment subject to strong vibration and shock

(7) Environment with corrosive gas, combustible gas

(2) Environment with splashing water and oil

(3) Near fire sources

(4) Environment with excessive organic solutions and salt

(5) Environment with direct sunlight and heat radiation

(6) Environment subject to strong vibration and shock

(7) Environment with corrosive gas, combustible gas

Related Products of Belt Actuators/Drives and Accessories

| Linear Guides for Heavy Load | Single Axis Actuator LXH45 | Single Axis Actuator LX30 | ||

|  |  | ||

| Representative model: SX2R24-640 | Representative model: LXH4520-B1-N-640 | Representative model: LX3010-B1-N-600 |

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.Incomplete part number.

Please use left hand selections to complete a part number.

Loading...Tải…

| Part Number |

|---|

| E-KUAC1510L-[340,400,460,520,580,640,700,760,820]-150 |

| E-KUAC1520L-[460,520,580,640,700,760,820]-150 |

| E-KUAC2010L-[400,460,520,580,640,700,760,820]-150 |

| E-KUAC2020L-[460,520,580,640,700,760,820]-150 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to ShipSố ngày giao hàng | Ball Screw Dia. (φ) | Ball Screw Lead (mm) | Overall Base Length [L] (mm) |

|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 40 Day(s) | 15 | 10 | 340 ~ 820 | ||

- | 1 Piece(s) | 40 Day(s) | 15 | 20 | 460 ~ 820 | ||

- | 1 Piece(s) | 40 Day(s) | 20 | 10 | 400 ~ 820 | ||

- | 1 Piece(s) | 40 Day(s) | 20 | 20 | 460 ~ 820 |

Loading...Tải…

Dimensional Drawing

Accessories Accessories |  Material Material |  Surface Treatment Surface Treatment | Quantity | Note |

| Hexagon socket head bolt M5×10 | Iron | Trivalent Chromate Treatment (Black) | 4 | For fixing bracket |

| Part | Base | Table | Motor bracket | Nut Bracket | Fixed Side Screw Support Unit | Support Side Bearing Housing | Stopper |

Material Material | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Iron | Aluminum Alloy | Resin |

Surface Treatment Surface Treatment | Black Anodized | Black Anodized | Black Anodized | Black Anodized | Ferroferric Oxide Protective Film | Black Anodized | - |

Specification Table

| Part Number | Selection | Rolled Ball Screw | W Workbench Width | H Total Height | H1 Guide Height | H2 Axis Height | Table | |||||||

Type Type |  No. No. |  L LBase Length |  L1 L1Table Length | Diameter | Lead | W | t2 | M1 | P1 | P2 | ||||

| E-KUAC | 1510L 1520L | 340 | 150 | 15 | 10 20 | 220 | 74 | 28 | 32 | 220 | 22 | M5 | 120 | 195 |

| 400 | ||||||||||||||

| 460 | ||||||||||||||

| 520 | ||||||||||||||

| 580 | ||||||||||||||

| 2010L 2020L | 20 | 89 | 39 | 40 | ||||||||||

| 640 | ||||||||||||||

| 700 | ||||||||||||||

| 78 | 28 | 34 | ||||||||||||

| 760 | ||||||||||||||

| 820 | ||||||||||||||

| Part Number | Base | Base Mounting Hole | Motor Mounting Related Dimensions | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Type | No. | W1 | H4 | t1 | h1 | P3 | h | Q | S | P.C.D | D | D1 | H3 | N | N1 | N2 | N3 | d | M2 | R | ||||||||||||||||||||||||||||||||||||||||

| E-KUAC | 1510L 1520L | 208 | 49 | 12 | 20 | 120 | 11.5 |

|

| 70 | 50 | 45 | 62 | 45 | 5 | 40 | 15 | 10 | M5 | 10 | ||||||||||||||||||||||||||||||||||||||||

| 2010L | 61 | 29 | 70 | 57.5 | 39.5 | 20 | 12 | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2020L | 55 | 20 | 64 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

*L=340 is suitable for 1510L only, and L=400 is suitable for 1510L and 2010L only.

■Applicable Servo Motor Table

■Precision·Allowable Static Load

■Applicable Servo Motor Table

| Manufacturers | Part Number | Output Power (W) | Square Flange |

| Yaskawa Electric | SGM7J-02 | 200 | □60 |

| SGM7J-04 | 400 | ||

| Mitsubishi Electric | HG-MR23 | 200 | |

| HG-KR23 | 200 | ||

| HF-MP23 | 200 | ||

| HF-KP23 | 200 | ||

| HG-MR43 | 400 | ||

| HG-KR43 | 400 | ||

| HF-MP43 | 400 | ||

| HF-KP43 | 400 |

■Precision·Allowable Static Load

| Part Number | *Positioning Repeatability (mm) | Allowable Static Load (kg) | *Parallelism (mm) | ||||||||||||||||||||||

| Type | No. | Horizontal | Vertical | ||||||||||||||||||||||

| Rolled Ball Screw E-KUAC | 1510L | ±0.05 | 2897 | 153 |

| ||||||||||||||||||||

| 1520L | |||||||||||||||||||||||||

| 2010L | 4345 | 169 | |||||||||||||||||||||||

| 2020L | |||||||||||||||||||||||||

Ball Screw Coupling Side Shaft End Alterations

| Alterations | Code | Spec. | |||||||

| Machining fixed side shaft end keyways | KC | Adds keyways. KC= 1mm increments Ordering Code KC10 |

| ||||||

| |||||||||

| Machining fixed side shaft end keyways | KLC | The machining position of keyways can be specified. K, S= 1mm increments Ordering Code KLC-K5-S2 |

| ||||||

| |||||||||

| Machining fixed side shaft end plane | SC | Adds planes. SC= 1mm increments Ordering Code SC7 |

| ||||||

| |||||||||

| Machining a plane at fixed side shaft end (2 places) | SWC | Adds planes at 2 places (90° position). SWC= 1mm increments Ordering Code SWC7 |

| ||||||

| |||||||||

■Single Axis Actuators Cover Specification Optical Sensor

■Cover Specification Optical Sensor Dimensions Table

| Applicable Part Number | Code |

| E-KUAC 1510L/1520L | CW1 CW2 CW3 |

| E-KUAC 2010L/2020L |

Basic InformationThông tin cơ bản

| Types of Ball Screws | Rolled | Motor Type | Servo motor type | Table Width W(mm) | 200 |

|---|

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer toCác thông số kỹ thuật và kích thước của mã sản phẩm có thể không được bao phủ đầy đủ. Để biết chi tiết chính xác, hãy tham khảo manufacturer catalogsdanh mục nhà sản xuất ..

Frequently asked question (FAQ)FAQ

- Question:Question: Do single axis units come with couplings?

- Answer:Answer: Single axis units do not come with couplings. MISUMI has recommended coupling models. Please select the appropriate coupling model referring to the "Examples of Applicable Coupling - Models" in the Specification Table for Single Axis Unit Selection.

- Question:Question: Is the optional sensor already installed on the body of the single axis unit when the product is shipped?

- Answer:Answer: When the single axis unit is shipped, the sensor is not installed on the body. The sensor unit is packaged separately and shipped as an accessory in the original packaging carton for the body of the single axis unit. Upon arrival of the product, the customer needs to install the sensor himself.

- Question:Question: Do you sell single axis units in a set along with a motor?

- Answer:Answer: Single axis units are not sold in a set along with a motor. The customer needs to select and purchase the motor himself. You can choose the appropriate motor model referring to the "Motor Application Table" in the MISUMI catalog.

- Question:Question: How to install the sensor?

- Answer:Answer: The installation method of the sensor varies with the specific operating conditions of the customer. The commonly used method is to install an origin sensor in the middle of a single axis unit and a limit sensor at both ends.

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy